Machines

OTB offers a wide variety of stock machinery for trimming, shaping, coping, and sanding. Our stock machinery selection ranges from manual single station machines to fully automated production lines.

SEI Series Shaper

The SEI Series Shaper features a heavy cast base with a motorized NC controlled outboard fence. It comes standard with an HSK 63-F spindle and belt fed power feeder.

XRT Series Coping Machines

From the simplicity and the effectiveness of the XRT.5 to the precision and innovation of the XRT Duo. The XRT series can handle all of your coping needs.

Single & Double End Tenoners

All OTB single and double ends all start with a strong and durable cast iron base, a tried and true tenoner chain system. Control hardware that is stocked and fully supported by US offices, is then installed by OTB. Each machine is then built and programmed to the customers specifications. Capabilities that include complete servo axis control, automatic tool change and HSK 63-F spindles.

Wide Belt Sanding, Grooving, & Slitting

Whitfield Wide Belt Sanders feature heavy-duty construction with sizes ranging from twenty-four inches up to fifty-three inches. Additional options include top and bottom sanding/grooving, waffle style vacuum belts, and hydraulic powered feed.

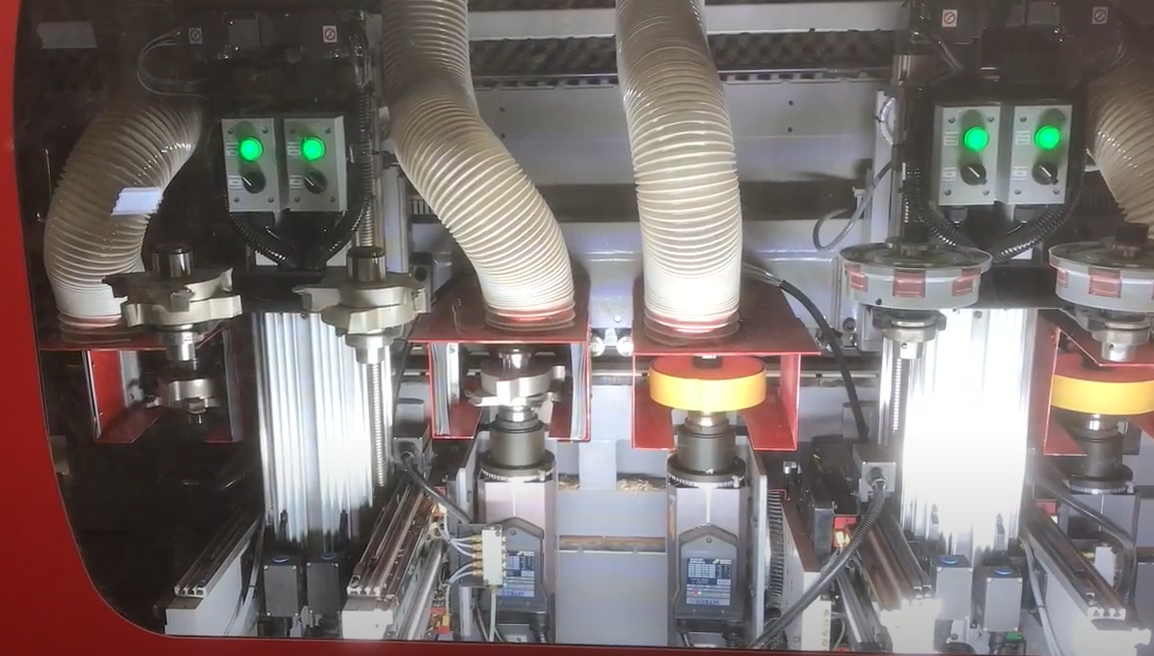

Boring & Perforating

OTB Perforating & Boring Machines are designed to maximize production and remove CNCs from boring processes. Boring machines may be placed in-line and integrated into existing equipment, or run as a standalone machine. Standard boring spacing options include 20, 40, & 50 mm spacing.

PXC & AXC Series Cross-Cut Saws

OTB Cross-Cut saws are built on a heavy-duty steel frame and are ideal for pre-sizing raw material, or finish sizing panels. Widths go up to 60 inches for perpendicular saws and 48 inches for angular saws (@ +/- 35°). All saws utilize an adjustable fence with pneumatic side and top pressure (servo side pressure option available)